Cross-cut

Overview

The cross-cut test is a very rapid and simple method for the assessment of single and multi-coat systems. Here, cuts in a 30° angle (method A) or right-angle (method B) are executed so that you receive a lattice pattern or an X-shape. These test methods can be used as quick pass/fail tests. When applied to a multi-coat system, assessment of the adhesion of individual layers of the coating among each other may be carried out.

Choice of the appropriate cross-cut method

- Methode A (X-cut) for tests in accordance with ASTM D 3359 with thickness > 125 µm (4.92 mil)

- Methode B (lattice pattern) for tests in accordance with ISO 2409 with thickness 0 – 250 µm (0 – 2.36 mil) and ASTM D 3359 with thickness <125 µm (4.92 mil)

Choice of the appropriate spacing of cuts (method B) in accordance with ISO 2409:

- 0 to 60 µm (0 to 2.36 mil) (Film thickness), hard (Substrate), 1 mm (0.04“) (Spacing of cuts)

- 0 to 60 µm (0 to 2.36 mil) (Film thickness), soft (Substrate), 2 mm (0.08“) (Spacing of cuts)

- over 60 to 120 µm (Film thickness), hard or soft (Substrate), 2 mm (0.08“) (Spacing of cuts)

- over 60 to 250 µm (2.36 to 4.72 mil) (Film thickness), hard or soft (Substrate), 3 mm (0.12“) (Spacing of cuts)

Choice of the appropriate spacing of cuts (method B) in accordance with ASTM D 3359:

- 0 to 50 µm (0 to 2.0 mil) (Film thickness), 1 mm (0.04“) (Spacing of cuts)

- 50 to 125 µm (2.0 to 5 mil) (Film thickness), 2 mm (0.08“) (Spacing of cuts)

ZCT 2160

Cross-cut Templet

Small, sturdy test equipment for determination of adhesion of thin and thick, hard single or multi-coat systems.

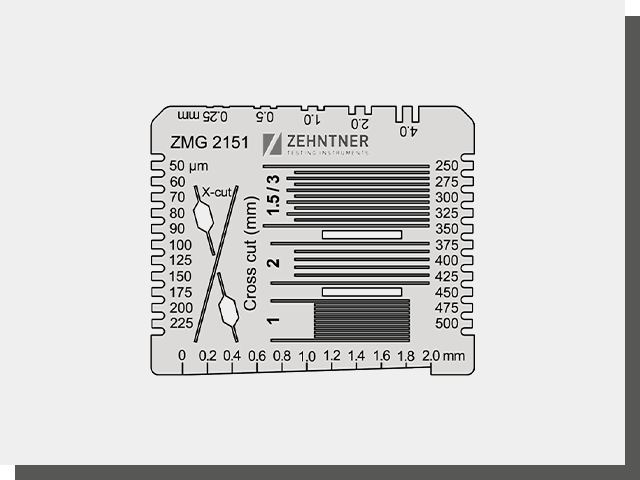

ZMG 2151

Multi-purpose Gauge

Multi-use: Cross-cut tester for adhesion assessment, applicator for wedge-shaped layers of coating materials, levelling applicator for determination of levelling properties and wet-film thickness gauge for testing the film thickness.

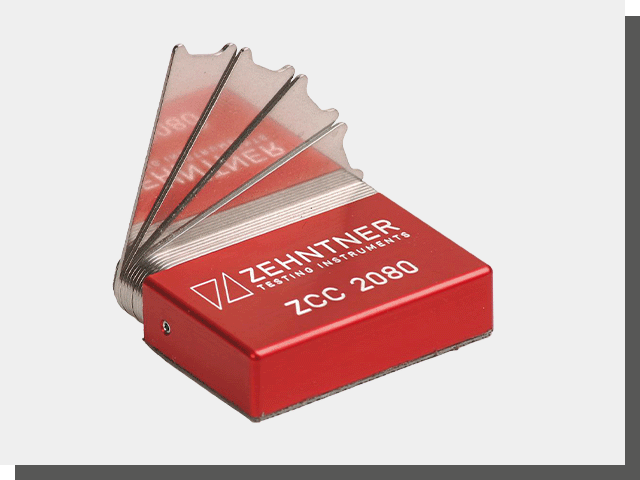

ZCC 2080

Cross-cut tester

Sturdy cross-cut tester with stainless steel shims for adhesion tests of single or multi-coat systems.